Sound Design, Starting with Tonewood Selection

Designing the Tone:

How Tonewood Shapes Sound

The species, grade, and processing techniques of each tonewood play a defining role in shaping a guitar’s tonal character, volume, and resonance.

When strings vibrate, their energy travels through the wood, setting the air inside the body into motion. These vibrations create sound waves that become the voice of the guitar.

That’s why selecting and preparing the right tonewood is one of the most important steps in the very first stage of guitar building.

At Crafter, every decision—from the type of wood to its structure and grade—is a conscious act of sound design.

We approach this process with deep sincerity.

Understanding the natural properties of each tonewood and designing a structure that draws out its fullest potential—this is where guitar-making begins for us.

Book Matching: Staring of Tonewood Crafting

Precision Crafting That Marries Acoustics with Aesthetics

Book matching is a tonewood cutting technique where a single piece of wood is sliced and opened like the pages of a book, creating a mirrored, symmetrical pattern. This not only delivers a visually stunning result, but also provides a consistent tonal foundation for the guitar body.

Because both halves come from the same wood, they share identical elasticity and physical properties. This symmetry allows for a more balanced vibration across the top or back plate—making book matching not just a matter of visual beauty, but a key step in establishing a tonal platform on which we can shape and craft our unique sound.

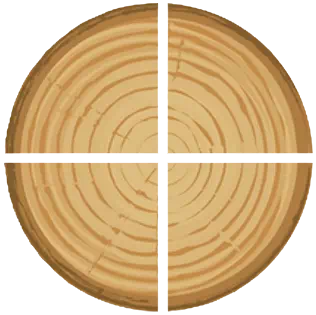

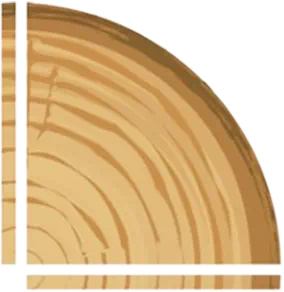

1. Cutting solid logs vertically into segments suitable for crafting 'Tonewood'.

2. Each segment is precisely sliced into 'Soundboards' that match the size and shape of a guitar body.

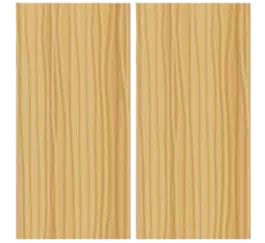

3. Book Matching: Like opening a book, two soundboards are arranged in perfect mirror symmetry.

4. Through Book Matching, we achieve both visual harmony and a tonal foundation on which to craft our sound.

Tonewood Drying

Strength Tempered by Korea’s Four Extreme Seasons

Korea’s climate swings from –15°C with near-zero humidity in the winter to over 35°C with up to 99% humidity in the summer. Our tonewoods are air-dried naturally over long periods through these intense seasonal shifts—gaining structural resilience and tonal maturity.

At Crafter, we believe that wood exposed to such varied and repeated cycles of temperature and humidity gradually optimizes its responsiveness and durability.

Before being crafted into guitars, each tonewood undergoes a final seasoning process—Crafter’s signature, confidential technique that completes the natural drying journey and prepares the wood for its role in a finely crafted instrument.

247: Constant Temperature, Constant Humidity

A Climate-Controlled Room

Imprints Memory Into Tonewood

At Crafter, our climate-controlled room maintains ideal conditions all year round—even on weekends, holidays, and after hours. [Temperature: 20–25°C / Humidity: 45–55%]

Within this stable environment, each tonewood is given time to stabilize and adapt before the building process begins. For about two weeks, the wood undergoes its final phase of shrinkage, expansion, or subtle warping. Once shaped and trimmed in this setting, the tonewood ‘remembers’ these conditions—locked in at its most balanced state.

That’s why, when guitars are later stored in a similar environment, they tend to return to their original shape and tonal balance. We recommend maintaining consistent temperature and humidity—so your guitar can hold onto the memory of the moment it was born and stay in the condition where it sounds its very best.